Chiller Use in Plastic Processes

- cemschiller

- Blog-En

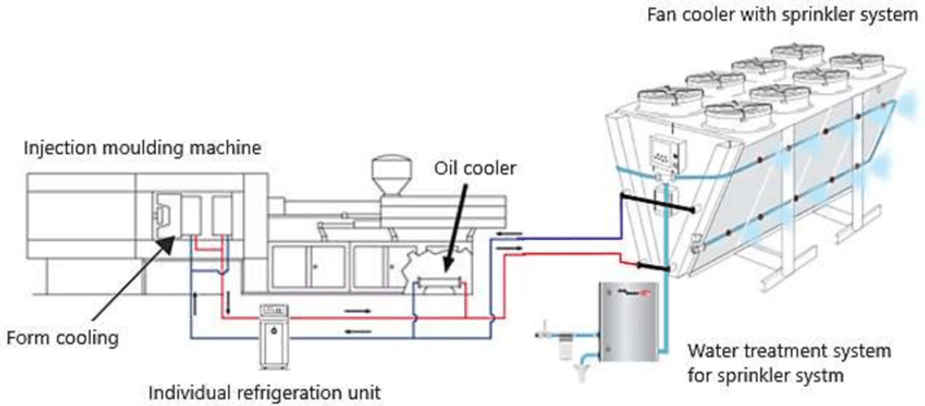

Chillers are cooling equipment that play a critical role in plastic production processes. They are used especially in injection molding, extrusion and similar processes to cool and shape plastics.

Why Are Chillers So Important?

- Quality Product: Chillers significantly increase the dimensional accuracy, surface quality and mechanical properties of plastic parts by providing fast and even cooling of molds. In this way, flawless and repeatable products are obtained.

- Shortening Cycle Time: Rapid cooling increases production efficiency by shortening the production cycle. This reduces production costs and increases profitability.

- Extension of Mold Life: Equal and fast cooling extends mold life by reducing thermal shocks in molds. This reduces maintenance and spare parts costs.

- Energy Efficiency: Modern chillers are equipped with high energy efficient technologies. In this way, energy consumption is reduced and production costs are reduced.

- Environmentally Friendly Production: Thanks to energy efficiency and less waste production, chillers contribute to environmentally friendly production

Areas of Use of Chillers in Plastic Processes

- Injection Molding: In this method, where the product is obtained by injecting and cooling the molten plastic material into the mold, chillers provide fast and even cooling of the molds.

- Extrusion: In the process of compressing the plastic material from a mold to create a continuous profile, chillers provide cooling of the mold and keeping the dimensions of the product under control.

- Thermoforming: In the process of drawing the heated plastic sheet onto a mold and shaping it, chillers provide cooling of the mold and maintaining the shape of the product.

Conclusion

The importance of chillers in plastic production processes is quite great. They offer many advantages such as quality products, high efficiency, long-lasting molds and environmentally friendly production. For this reason, investing in chillers is a profitable solution in the long term for every business that produces plastics.